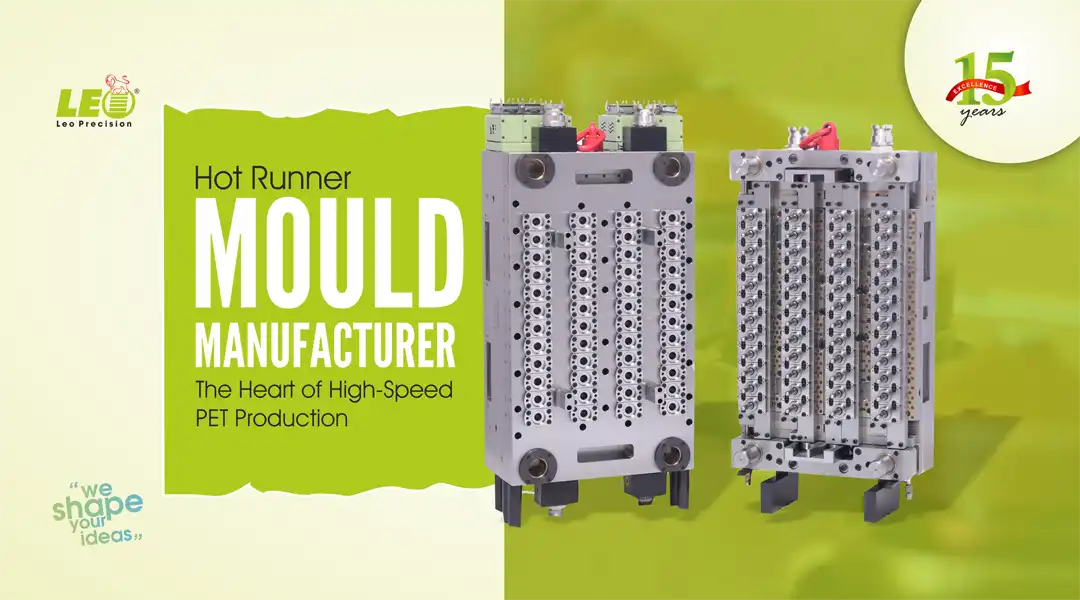

In the high-speed world of PET packaging, efficiency is everything. That’s why

hot runner moulds have become a must-have for producers looking to minimize

waste and maximize productivity. As a trusted hot runner mould manufacturer, Leo

Precision delivers reliable, precision-driven solutions for PET preform

production.

Why Hot Runner Systems Matter

Unlike cold runner moulds, hot runner systems maintain the plastic in a molten

state throughout the runner system, resulting in:

-

No gate vestige on preforms.

-

Reduced material wastage.

-

Shorter cycle times.

-

Improved part consistency.

Our Expertise in Hot Runner Tooling

Leo Precision designs and manufactures complete hot runner injection moulds, as

well as individual hot runner components like:

-

Balanced manifolds.

-

High-flow nozzles.

-

Thermally optimized heaters.

-

Valve gate systems.

These are tailored for compatibility with leading machines such as Husky, SIPA,

ASB, and others, ensuring integration without performance compromise.

Efficiency Backed by Engineering

Our hot runner systems are engineered with a strong focus on:

-

Thermal uniformity.

-

Leak-proof operation.

-

Easy maintenance and part replacement.

-

Extended operational life.

Conclusion

Whether you're expanding capacity or replacing legacy systems, Leo Precision’s

hot runner moulds provide a profitable path to faster, cleaner, and more

efficient PET production.