Caps and Closures Moulds

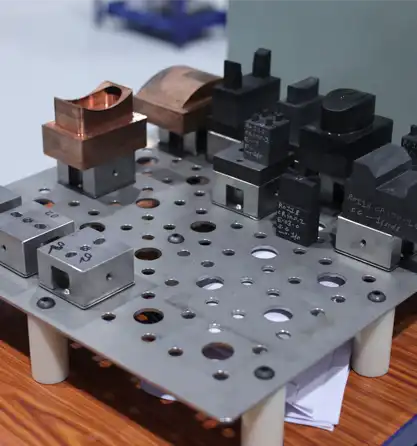

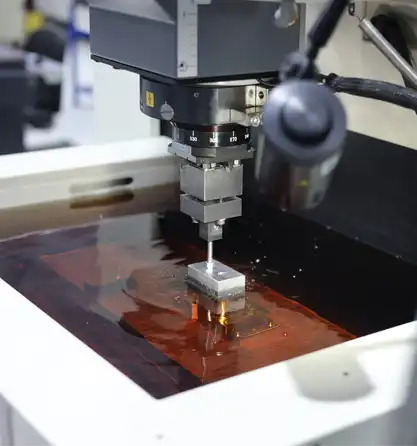

We are uniquely placed globally to offer complete solution to the Rigid Packaging Industry by offering Caps and Closure moulds along with Preform & Bottles Mould which we manufacture. Our expertise ranges from moulds with simple bump off caps, flip-top caps to complex moulds with in-mould closing and un-screwing mechanisms.