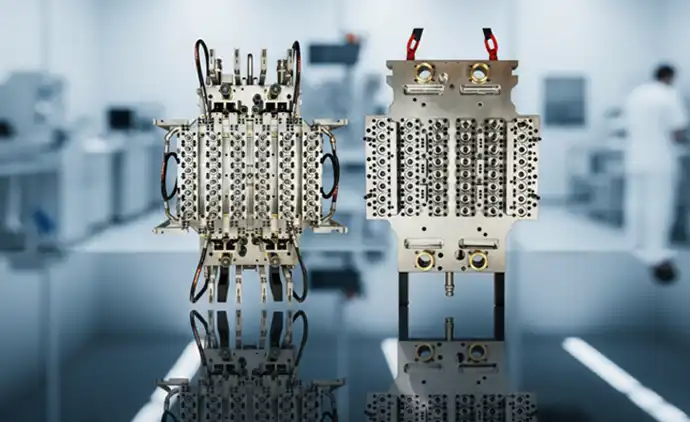

OEM Molds and Conversion Kits

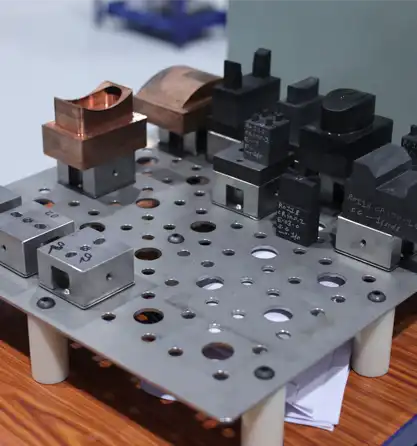

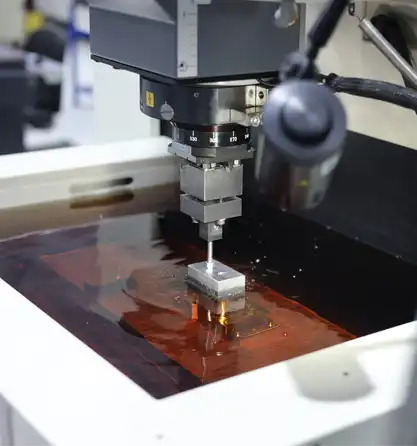

We are equipped with all the capabilities to offer your solutions on your PET injection moulding systems from Husky, SACMI, SIPA, Krauss Maffei and others. Our highly precise machining gives us consistency across all the stacks enables us cavity to cavity and mould to mould interchangeability of inserts. We can offer cold halves up to 144 cavities including post cooling systems.